Introduction

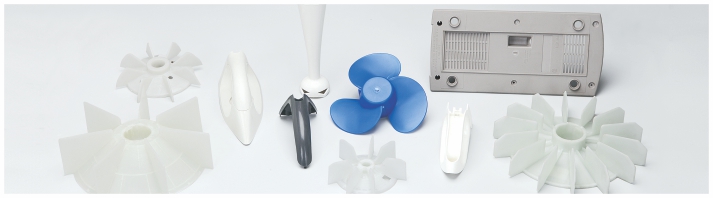

Dpron Polypropylene Compounds has the advantages of excellent comprehensive properties, good chemical stability, good shape processing performance and relatively low cost. It is adapted to a wider range of application requirements through modifying, copolymerization, grafting, blending, reinforced filling, Glass filling etc.

Features for Dpron Compounds

- Good fatigue resistance

- Good hinging properties

- Good chemical stability

- Reasonably economical

Chemical Structure of Polypropylene

We have a range of Polypropylene Compounds for the use in injection Moulding. It is compounded with various Minerals (Talc, calcite, Wollastonite & Mica), Chemically coupled & Uncoupled Glass and other Chemical additives to give properties like High Flow, High Gloss, High Modulus- High Impact, Flame Retardant, It is available in Natural, Black & Colours.

We have a range of Polypropylene Compounds for the use in injection Moulding. It is compounded with various Minerals (Talc, calcite, Wollastonite & Mica), Chemically coupled & Uncoupled Glass and other Chemical additives to give properties like High Flow, High Gloss, High Modulus- High Impact, Flame Retardant, It is available in Natural, Black & Colours.

Product Description

- 10% - 40% Mineral filled compounds.

- 10% - 40% Glass reinforced compounds.

- Impact modified compounds for automobile applications.

- Mineral filled high gloss compounds for appliances.

- Flame retardant compounds.

- High tensile, chemically coupled glass compounds.

- PP - Long term heat ageing (LTHA) compounds.

- Special compound for energy meter enclosures.